Part 2 Ready for summer crop 2022 - The game plan

Sep 8, 2022Once you have your soil test results, you can apply the 4Rs of nutrient management to hone your fertiliser program. Each paddock, rotation and farm will have its own requirements, so generalising is difficult, but this insight can be used as a guide.

Download this article

RIGHT RATE

The fertiliser rate will depend primarily on crop demand, but also application timing, application strategy and product choice. Using decision support tools like Nutrient Advantage® Pro will help estimate the right fertiliser rate. There are also mineralisation estimation tools, crop models, and farming systems sites that can help ground truth your conclusions. But be aware, this year we are likely starting with an N-depleted root zone.

RIGHT TIME

N should be applied with some lead time prior to the most rapid crop uptake period. A soil test is your best guide to whether a pre-plant or planting application is needed, or if an in-crop application strategy will be more appropriate. Splitting N applications is a way of reducing the potential for denitrification losses by adding less nitrate-N at any one time. The key is to ensure there is enough soil-N for early crop development.

Applications at planting need to consider the seed safety risks of ammonium-based nitrogenous fertilisers, along with the salt index (osmotic) effects. Consider seed bed utilisation; opener type; soil moisture; and the diffusion area created by disc planters placing fertiliser directly with seed on wide summer crop rows.

In-crop fertiliser should only ever be applied to actively growing crops. In years like this it pays to be flexible and prepared to match applications to paddock conditions, trafficability and weather. Of course, the biggest risk is doing nothing and having an N deficient crop.

RIGHT PLACE/APPLICATION

Placement of N fertiliser in risky loss conditions should be quite deliberate and prescribed, considering farmer equipment, spatial accuracy (GPS guidance etc.) row spacing, management skill and ability to execute in a timely manner.

Broadcasting

If broadcasting or topdressing, be aware that N fertilisers are at risk of significant loss (i.e., volatilisation), where high rates are applied in combination with:

- heavy alkaline or calcareous soils;

- wet but drying soils;

- warm to hot soils;

- insufficient follow up rainfall /irrigation within 24 to 48 hours;

- incomplete physical incorporation of the fertiliser

Sidedressing

Placing N to the side of the plant line early in the season is an acceptable practice, if you are mindful of:

- the proximity of equipment/opener and fertiliser to crop roots;

- the crop stage and access to the plant line or interrow;

- closing and sealing the soil furrow or application zone to reduce volatilisation (urea etc.) or vapour loss (BIG N); and

- ensuring that the fertiliser band is within reach of the crop root system to allow adequate recovery in time for peak crop N uptake.

Foliar application

Foliar application can deliver more accurate placement than broadcast spreader-type applications but is not without risk (particularly if using flat fan nozzles).

There are limits (based on crop age) to the rate that can be applied in a single foliar application. For example, Urea Solution (26% N) is best used in several small applications rather than a single application trying to supply the whole season’s N requirement. In addition, the higher ambient temperatures and more variable and hostile summer conditions at application can result in leaf scorch and foliar damage. This can be exacerbated further if tempted to tank-mix other products.

Streamjet, Streambar or ’Y-Drop’ N applications can deliver the N fertiliser to the soil (rather than the foliage), but product choice (% and form of N) is important. Other considerations are:

- the terrain (hills, beds, or on the flat);

- the placement and proximity to the plant line which affects foliar contact and plant uptake;

- soil moisture both for trafficability and ability to absorb fertiliser;

- ·nozzle and application type and boom set-up to reduce leaf burn in row crops to an acceptable risk, especially if applied at earlier growth stages.

Water-run applications

Water-run N applications in irrigation systems work well but are not without their own issues regarding product suitability, N loss, N availability, N travel time and deposition in the field/farm. In wetter growing seasons, where irrigation use can be low, water running would be a risky strategy. Easy N®, BIG N® and Urea Solution are popular products for this use pattern.

RIGHT PRODUCT

Product choice or specific specialty products like enhanced efficiency fertilisers (EEFs) can offer further risk reduction benefits, where the practices outlined above cannot alone mitigate or reduce the risks adequately.

Broadcast applications

Granular urea

Granular urea is the most widely used and applied N source as it fits the pre-plant, sidedress and broadcast markets well. Granular urea can be broadcast, however the risk of volatilisation (if not drilled and or incorporated by rainfall or irrigation) must be a consideration during spring, summer and autumn.

Green Urea NV®

For broadcast applications, urease inhibitors like IPF’s Green Urea NV® provide more time to receive adequate rainfall or irrigation to incorporate the N. Green Urea NV holds as stable

urea for a period of up to 14 days, not allowing the hydrolysis process to commence, effectively reducing the risk of ammonia volatilisation.

Drilled/banded pre-plant and early in-season sidedress applications

eNpower® urea

eNpower® is a nitrification inhibitor designed to reduce the losses to denitrification and leaching. Widely used in Europe and proven in Australia, the active ingredient DMP has been shown to hold nitrogen in the ammonium form for longer, slowing the nitrification process and reducing the time that N is nitrate and reducing the risk of loss to dentification and leaching.

BIG N®

BIG N will be available as a pre-plant, sidedress and water-run application system until the end of 2022.

Easy N®

Easy N is IPF’s liquid urea ammonium nitrate product, containing 42.5% N w/v. It can be used for pre-plant soil, early in-crop banded, and streamed in-crop applications. It can deliver adequate application rates quickly and easily to the soil, close to active roots. The three forms of N allow quick plant uptake of the immediately available nitrate-N form, then uptake of the ammonium and urea forms later as they nitrify.

Foliar flat fan nozzle applications in summer crops are not recommended. The risk of leaf scorch and the reaction from rapidly changing conditions during application, and for two to three days after, increases the variability of results.

SORGHUM EXAMPLE 2021-22

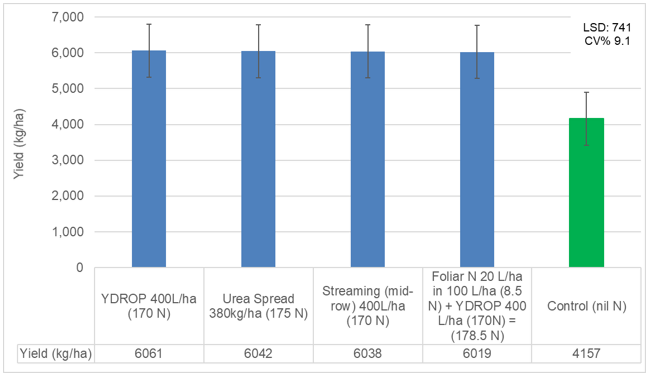

Pacific Seeds research (Philp, T. 2022, pers comm.) from their Southern Darling Downs research farm demonstrated a similar grain yield result from four in-crop nitrogen application strategies (Figure 1). IPF and Pacific Seeds collaborated on the trial design. The site started with 110 kg/ha nitrate-N in the 0-90 cm. The site received 30 mm three days after the N applications. Sentinel IG (a Pacific Seeds grain sorghum hybrid) was sown on 28/10/2021 at 90,000 seeds/ha, with no pre-plant or at-sow nitrogen applied.

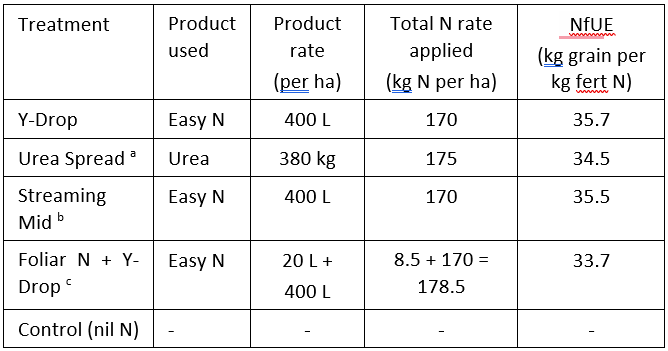

The in-crop N treatments used urea and Easy N, applied by four different application methods at the six-leaf growth stage (Table 1). Each treatment delivered 170 kg N/ha – intentionally well above commercial practice and greater than optimum for the trial.

Table 1: Pacific Seeds Foundation Farm trial treatments applied with various application strategies and products at the six-leaf stage compared to the nil N control.

a not incorporated

b Streamjet streaming nozzles onto mid-row soil

c Foliar (total vol 100 L/ha) flat fan nozzles + Y-Drop

While the N application rate was high, it clearly demonstrates that in seasons where the starting N is low, in-crop product choice and application strategy are of smaller consequence than not applying any N at all. This is shown by the control (nil N) which produced approximately 2 t/ha less grain yield than any of the other N treatments.

Figure 1: Pacific Seeds Foundation Farm Allora Qld, grain yield of Pacific Seeds Sentinel IG from 170 kg N applied with various application strategies and products at 6 leaf stage compared to the nil N control. Starting soil nitrate-N of 110 kg/ha in the 0-90 cm.

Further evidence that the N product chosen did not influence the yield result significantly is shown by the N fertiliser use efficiency (NfUE) data (kilograms of grain produced per kilogram of nitrogen fertiliser applied). However, slight differences between products were noted. The NfUE of the combined Foliar and Y-Drop application had the lowest NfUE of all treatments (see Table 1). The Urea Spread treatment was lower than Streamed-mid or Y-drop applications of Easy N.

OTHER CONSIDERATIONS

In developing your plan for what might be a very wet season it may be worth considering:

- opting out of a summer cash crop and planting short-season cover crop to mop up excess profile moisture and avoid having to add fertilise an already wet soil profile, lessening the denitrification risk;

- improving paddock drainage by earthworks or employing furrows;

- controlled traffic systems to effectively raise beds to allow for better drainage.

DON'T FORGET ABOUT SULPHUR

Recent soil test results from the Nutrient Advantage® laboratory indicate many paddocks have lower than usual topsoil sulphur (S) levels (85% less than 10 mg/kg).

When planning a sulphur strategy, consider not just the soil test results but the potential contribution from S mineralisation – likely in warm, wet, aerated soils with high organic matter – and any recent sulphur applications from products like gypsum, Gran-Am® or sulphate of potash. Any ammonium phosphate fertiliser used will likely contain some small amounts of sulphur (~1.5% S in MAP).

You can supply additional plant-available sulphate sulphur both to this and the next crop by:

- adding granulated ammonium sulphate (Gran-Am 24% S) to pre-plant N applications;

- using Granulock® Z (4% S) or Granulock Z Extra (5.4% S);

- adding Granulock BIG Z (16.1% S) or Zinc Sulphate Monohydrate (17.2% S) to your AP blend

IN CONCLUSION

Be aware of the risks and quantify the losses you have likely experienced so far. This should form the basis of an informed N plan for whatever (else) this wet season may throw at us. And remember, with N, doing nothing or hesitating can also be a risk.

With full moisture profiles, healthy grain prices and reasonable returns on offer, there are many practices and product tactics we can employ to get through. So ‘measure to manage’ has never been a truer statement to close my advice to you this season.

FURTHER INFORMATION

For more information or advice about summer crop nitrogen strategies, feel free to contact me on 0417 896 377 or bede.omara@incitecpivot.com.au. You can also contact: David McRae david.mcrae@incitecpivot.com.au

DISCLAIMER

Incitec Pivot Fertilisers manufactures and sources fertilisers from other suppliers. The fertiliser supply chain extends beyond the company’s direct control, both overseas and within Australia. Incitec Pivot Fertilisers hereby expressly disclaims liability to any person, property or thing in respect of any of the consequences of anything done or omitted to be done by any person in reliance, whether wholly or in part, upon the whole or any part of the contents of this article.

This is a guide only, which we hope you find useful as a general tool. While Incitec Pivot Fertilisers has taken all reasonable care in the preparation of this guide, it should not be relied on as a substitute for tailored professional advice and Incitec Pivot Fertilisers accepts no liability in connection with this guide.